Building-Fa?ade Maintenance Robot System

Motivation

The number of buildings equipped with façades (curtain-walls) is increasing all over the world. These fa?ades must be periodically maintained with manual procedures that are supposed to be costly and risky.

Automation and robotics technologies allow safe and environmentally friendly facade cleaning, monitoring, and painting, which also reduce the cost of these tasks. These systems resolve the current safety problems associated with difficult and dangerous access, contributing to a zero injury and fatality working practices.

In this project, we are developing the Built-in Facade Maintenance Robot system with Docking Station based on vertical climbing mechanism. The robot systems will be implemented on a real building.

Research Territories

Development of Vertical Climbing Mechanism

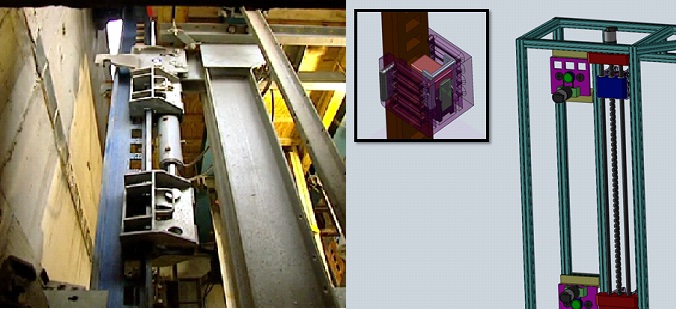

Many high-rise buildings use commercial carrier systems (a gondola) that move on the fa?ade for manual cleaning. However, our project consists of Built-in Guide-Rail System mounted on the high-rise buildings, inch-worm mechanism for vertical climbing that is frequently used in construction fields due to its safety nature despite complicated climbing patterns.

Development of Horizontal Moving Mechanism

The Horizontal Moving Mechanism is composed of intersection wheel mechanism and lifting system. For removability, it is designed to be lifted out from the horizontal rail and set on the vertical docking unit.

Reference

- S. Moon , D. Hong , J. Kim “Design of Climbing Mechanism for High-Rise Building Maintenance”, 2010 KSPE-Spring

- S. Kim , D. Hong , S. Moon “Development of Guide Rail Intersection Cross over Mechanism with Gears” , 2010 KSPE-Fall

Patents

- 10-2010-0045560 , 2010-05-14 “Outer Wall Climbing Robot for Maintenance of Building Outer Wall”

- 10-2010-0045396 , 2010-05-14 “Maintenance Robot System based on Modular Climbing Mechanism”

Sponsor

The work presented in this paper was funded by BMRC (Building-Fa?ade Maintenance Robot Research Center), supported by Korea Institute of Construction and Transportation Technology Evaluation and Planning (KICTEP) under the Ministry of Land, Transport and Maritime Affairs (MLTM).