Optimal Control and System Dynamics Analysis for Surface Mounting Device (SMD)

Research Outline

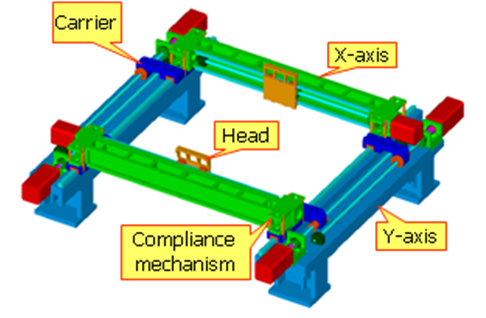

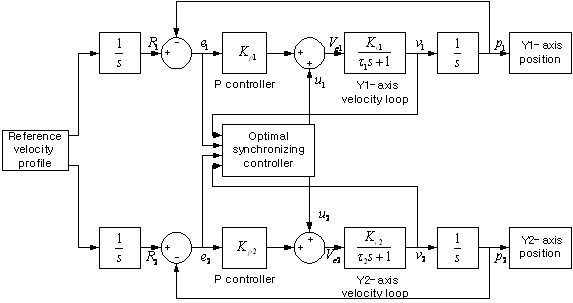

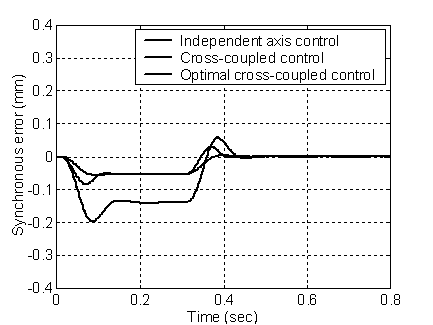

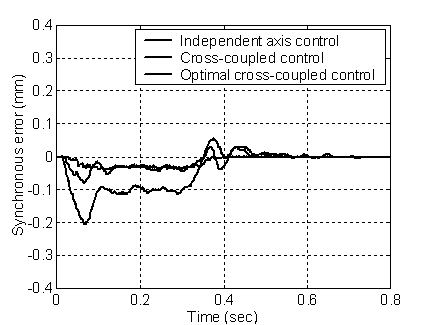

The present research deals with the development of synchronizing controller for dual-drive servo system that is often used for SMD (Surface Mount Device) assembly machine. Instead of coordinating the commands to the individual feed drives and implementing closed position loop control for each axis, this work is achieved by the evaluation of an optimal cross-coupled compensator aimed specifically at improving synchronous accuracy in dual feed drives. The optimal control formulation explicitly includes the synchronous error in the performance index to be minimized. In this research, surface chip mounter is used for experiment. It demands to synchronize the positions of its two primary driving axes. The system is modeled as the first order approximation and cross-coupled optimal synchronizing controller is designed. The synchronizing control is simulated and experimented with actual system for various velocity profiles. The results show that the proposed controller reduces the synchronous error considerably, compared to the conventional uncoupled control for the dual-drive system.

- Control algorithm development for high speed and high precision system

- Improvement of assembling productivity

- Experiments with real product base

Details

- Servo-motor control for independent axes

- Optimal control algorithm development for high speed and high precision system

- PC-based experiments with prototype base

- System dynamics analysis

Institutes

- Prime institute

- Mechatronics & Field Robotics Lab., Dept. of Mech. Engineering, Korea Univ.

- Cooperative institutes

- Samsung-techwin

- Research period: 2001. 8. 30. ~ 2003. 8. 29.

Available Tools and Equipments

- S/W

- MATLAB, MATLAB simulink

- ABAQUS

- H/W

- DS1103 PPC controller board

- PMAC

Research Vision

- Mechatronics system

- Mechanical system: surface mounting device

- Electrical system: controller design and operation

- Industrial cooperation

- Control application with real industrial product

- Actually applicable system development